Calling out your parts properly insures you get what you want the first time. If you don’t do it right, you risk getting the wrong parts. That wastes time and money for everyone. If it’s a custom-made part, you’re stuck with it. Neither you nor your vendor wants that, but not all vendors will call you and interrogate you as to what you mean because assumptions will be made, and assumptions are bad. (The excerpt below is from a previous blog post.)

The correct order is always Diameter x Thread/Pitch x Length, Head / Drive / Description / Grade / Plating / Add-Ons (not all items are applicable to all parts). Make sure that the information for your bolt is included in the correct order. In metric parts always put a lower case “m” in front of the diameter without a trailing space. (Keep in mind Europeans use a comma as a decimal delimiter so you may see a comma instead of a period in Metric parts so m3.5 and m3,5 are the same thing).

Many people tend to put related words like FINE after the size call-out to remind people it’s a fine thread. (You can also put LEFT-HAND in this position as well for a left-handed part!) A nut must match the bolt, or it won’t fit. Everyone knows that, right? In theory, you’re absolutely correct. In practice you are mostly correct (over 95% of the time) but some metric bolts will accept an imperial nut and vice-versa; the fit isn’t great, thus it can lead to some serious problems. For example, an 8-32 nut fits an m4 bolt sloppily. Should it work? No. Why does it work? Tolerances. All manufactured parts have tolerances and if one part is near the high side and another is near the low side you can have an inadvertent fit. And conversely a ¾-10UNC (US Standard) nut will not fit a ¾-10BSW (British Standard) bolt because the angle of the threads aren’t the same even though the threads per inch are identical!

If you ask for a ¾ x 4 Hex Bolt Grade 5, there are many parts we can provide that meet that specification. There is no way to know for certain what you want. We would typically offer you a ¾-10 UNC x 4 Hex Cap Screw Grade 5 with Zinc Plating as that’s what 90% of customers want. What if it’s full thread? Plain? Zinc/Yellow? UNF? BSW? Those are just five additional examples of many. The last one is particularly odious because BSW, UNC, and UNF nuts aren’t interchangeable, and the nuts won’t fit the bolts. Hence the necessity of properly calling out your product using correct terminology.

A good vendor (we at Hardware Everywhere can do this for corporate accounts) can associate your part number with our part number in their software. That means when you re-order, you can do so with either your part number or our part number and we can find it in the system and all paperwork will show your part number. Just let your salesperson know you’d like to do this.

For Military Specification Parts (MilSpec) you just include the MilSpec number, and no further description is required. If you aren’t building defense projects, avoid using MilSpec fasteners as they are far more costly than their commercial equivalents often by a factor of ten or more for the same exact fastener. Hardware Everywhere can provide MilSpec fasteners but they are not listed on the website by design because we have to ask the customer about TAA, PPAP, DFAR, and other concerns.

Screws (except Machine)

Let’s start with tapping screws (which also includes self-drilling screws, drywall screws, and particle boards screws.)

What are the elements here? You have a head, a drive, a diameter, a thread, a length, and a material and probably a plating.

Let’s put that in a form that is proper. In the fastener industry, we have a particular order which is: diameter-thread “x”1 length, head, drive, item, material, and plating. If specifying with a quantity, that always comes at the beginning of the call-out.

10,000 #8 x 7/8 Flat Phillips Type-A SMS 18-8 Stainless

(Some people like to write #8A instead of putting the type “A” in the description. That’s a matter of preference. Either is perfectly acceptable.)

We’ll discuss the mechanics of calling out the part in greater detail in the next section. This was just to give you a brief start in case you wanted only an introductory idea. Regardless, no matter what the item is, this is how it always works.

Screws (Machine) and Bolts

Let’s move on to machine screws and bolts which will constitute most of what you’ll order. For all IFI and DIN standard parts, the process is pretty simple.

Let’s put that in a form that is proper. In the fastener industry, we have a particular order which we mentioned in the previous section. Here we will discuss it in far more detail.

25M ¼-20 x 1-1/4 Pan Slotted Machine Screw Steel Nickel Plated

Quantities in the fastener industry use roman numerals for quantities. C = 100, M =1000 (never use K for thousand), MM = 1,000,000. You can also just write the quantity in regular numbers.

What if you have special requirements? Let’s say you want Domestic, Waxed, or special packing. Just add it to the end of the description as in the following examples:

25M ¼-20 x 1-1/4 Pan Slotted Machine Screw Steel Nickel Plated Made In USA

25M ¼-20 x 1-1/4 Pan Slotted Machine Screw Steel Nickel Plated with Wax

25M ¼-20 x 1-1/4 Pan Slotted Machine Screw Steel Nickel Plated Packed 250/box

When you see the item on a quote sent from your friendly Hardware Everywhere salesman, you’ll see 1/4-20 X 1-1/4 PAN SLOTTED M/S NICKEL1 as the description and if you look at our part number you will see 25C125MPSXN which is diameter (25 is decimal ¼”) and “C” which indicates coarse thread followed by the lengths (1-¼ is 1.25”). MPS stands for Machine, Pan, Slot in that order. There’s a three-letter code for most fasteners. If you want Phillips instead of slotted just change the “S” to “P” giving you MPP! X signifies low carbon steel, and the N is for Nickel plated.

Metric fasteners work the same way. Some people just put the DIN number instead of the description. For example, in Metric if that was a 6x35 DIN85A Nickel, you could describe it that way, but we’d still enter it as m6C35MPSXN, and it would say m6 x 35 PAN SLOTTED M/S NICKEL.

Nuts

Next, we have nuts which are little more complex. Certain types of nuts (Coupling Nuts for example) do have a length and it’s used just as with a bolt. Typically, if it’s an IFI standard nut, length isn’t included in the description but feel free to do so if it makes you feel comfortable. Nuts also can have special widths across flats (WAF) dimensions which are specified as ¼”AF, if needed). When you’re typing one thousand line items or more a day, leaving off those extra characters adds up quickly, so they’re only included if non-standard. If you have any concerns about what the standard dimensions are, there are specification sheets on the Hardware Everywhere website, or ask your friendly Hardware Everywhere salesman.

This would appear as 3/8-24 UNF Nylock Nut NE 18-8 Stainless w/Black Oxide and part number 37FNNXSO. What’s the UNF? UNC is standard coarse and UNF is standard fine thread. When calling out non-coarse threads, many people like to put the UNF (or other designator) so it’s clear to everyone that the item isn’t coarse thread. It’s just a redundancy to prevent errors.

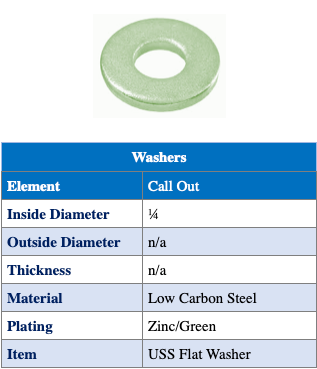

Washers

Next, we have washers which are more complex. Washers for USS, SAE, and F436 patterns do not typically include the outside diameter or thicknesses because they are part of the standard itself. Otherwise, outside diameter and thickness are always included.

One notable exception is military sized washers (but not made to military specifications) which are common in stainless, so asking for an 808 washer will get you a very specific size: it’s important to note “Size 808” will get you a commercial equivalent washer but if you write MS15795-808, you are demanding the actual military specification washer which is far more costly..

This would appear as ¼ USS Flat Washer Zinc/Green and part number 25NWFUXG. For the record, this washer is ¾ outside diameter and 1/16” thick. But since we know it’s USS, none of that has to be specified as it’s part of the specification. But if you want to write it, it’s okay. You can write ¼ x ¾ x 1/16 Flat Washer USS Pattern Steel Zinc/Green and while more information is better, in this case you might introduce confusion with all the redundant verbiage.

Wrapping It Up

If you’re specifying platings, and are curious, it’s done like this:

- Zinc. Commercial thickness is supplied unless otherwise standard). This is the silver color you are used to seeing.

- You may receive either Cr3/Cr3+ (Trivalent) for RoHS Compliant or Cr6 (Hexavalent) which is not RoHS Complaint

- Zinc 2µ (That means 2 microns thick instead of commercial)

- Zinc/Yellow (this is yellow colored Zinc often called Dichromate; Zinc comes in many colors with Yellow, Green, Black, Blue, and Red being the most common)

- Galvanized never use this term alone because it’s incomplete.

- Hot Dipped Galvanized (HDG) is what most people want

- Mechanical Galvanized (MG) is similar to HDG but it’s applied differently and isn’t quite as corrosion resistant.

- Electro Galvanized (EG) this is a commonly used term, but it’s NOT galvanized in the sense customers expect it to be. It’s just regular commercial zinc. We find this term to be inherently dishonest.

On the Hardware Everywhere website, you’ll see our part numbers listed with everything (ignore any leading zeroes as that is a technical issue for the website and not part of the call-out). We’ll happily give you a full description call out for any item you are ordering. If you have any questions, contact us – we’ll gladly answer you, and update this article if it’s warranted. Now, you have a basic understanding of how to call out any part to help you reduce errors in your supply chain.